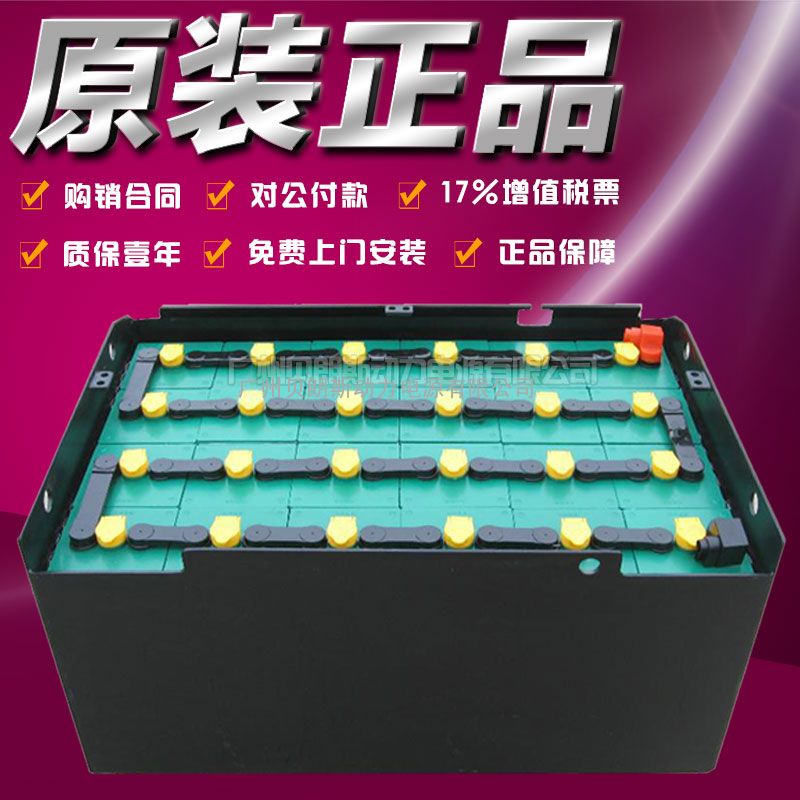

厂家直销林德E10叉车电瓶24V46***h,价格合理,型号:12-3PZS465是林德叉车专用蓄电池组,性价比高,贝朗斯品牌,品质媲美进口电瓶,标准的安装设计图纸,可避免客户对林德蓄电池的概念模糊化,林德贝朗斯叉车电池广泛应用各种林德车型,寿命达5年以上,应定期检查和调整电解液液面高度、纯度及密度:叉车蓄电池的电解液液面高度可用玻璃管测量。正常液面应高出隔板15~25mm。通常在10~15天检查一次,热天每周检查一次。一般情况下电解液不足时,应加注蒸馏水。除非确知液面降低是由于电解液贱出所致,否则不可补加稀释硫酸电解液。对于电解液纯度应每年化验一次,特殊情况电解液颜色出现异常时,应随时进行纯度化验。配制电解液时,所使用的硫酸溶液应符合GB4554-84,纯水应符合行业标准ZBK84004-89(若有新国标,应以国标为准)。对于需重新灌注的电解液,其配制的溶液密度为1.265g/cm3±0.005g/cm3(30℃),水与硫酸(密度1.835g/cm3)的体积比约为3.1:1。质量比约为1.7:1。

对于新蓄电池充电末期电解液的密度应为1.290g/cm3±0.005g/cm3(30℃)。配制电解液时,应按比例将硫酸徐徐加入水中,并用耐酸棒随时搅拌,使其混合均匀,切胡将水倒入硫酸中,以免发生事故。而对于需通过补加来调节电解液密度的,可用预先配制好的1.40g/cm3 的硫酸电解液来调整。注入电解液后需静置一段时间,待温度下降到35℃以下时方可进行充电。在寒冷地区使用的蓄电池,电解液密度可比规定值高0.020~0.030 g/cm3,而在炎热地区使用的蓄电池,其电解液密度可降低0.020~0.030 g/cm3。测量电解液密度时,还应同时测量电解液温度,并按表将测量的电解液密度值换算为15℃时的密度值。例如电解液温度为30℃时,测得密度为1.28 g/cm3,则换算成15℃时的密度为:1.280g/cm3+0.01=1.290g/cm3。再如,在-15℃时测得电解液密度为1.27g/cm3,则换算成15℃时的密度为:1.27 g/cm3-0.02=1.25g/cm3。根据实际经验,电解液在15℃时的密度每减少0.01 g/cm3,约相当于放电6%。

所以,如果已知电解液密度,就可以判断铅蓄电池的充放电程度。需要注意的是,对于进行大电流放电或刚加注过蒸馏水的铅蓄电池,不可立即测量电解液密度。叉车电瓶充电的电解液温度不得超过45℃。接近45℃时应减半充电电流或暂停充电,待温度降至35℃以下再继续充电,但需适当延长充电时间。蓄电池是否充足电可由以下几个方面来判断:

(1)电池电压或电解液密度连续2~3小时内保持基本稳定,

(2)电池内电解液液面产生强烈气泡,

(3)其充入电量为额定容量的4~5倍,充电时间约70小时。

在正常的工作条件下,叉车蓄电池都应该按规定放电后及时进行充电。正常充电(即补充充电)的方法;以分段衡电流充电法为例:蓄电池正常充电在*阶段用0.70I5(A)电流充电,当单体蓄电池平均电压达到2.40V时,第二阶段再用0.35I5(A)电流充电。充电量为放出电量的120%~130%左右,但新蓄电池前5次的充电量,应为上次放电量的150%左右。目前,电瓶叉车充电机大多为全自动控制型充电机,具体操作办法祥见充电机使用说明书。另外,当发生下列情况之一时,就必须进行正常充电:(1)电解液密度下降到1.150~1.200 g/cm3时。(2)冬季蓄电池放出电量25%,夏季放出50%时。Linde forklift battery manufacturers selling E10 24V46***h, the price is reasonable, is a special type: 12-3PZS465 Linde forklift batteries, cost-effective, shell lens brand, quality comparable to imported batteries, installation of standard design drawings, customers can avoid the concept of Linde battery fuzzy, Lindebei lens is widely applied to all kinds of Linde forklift battery models, life of 5 years. Above, should regularly check and adjust the electrolyte level, purity and density measurement of electrolyte level available glass tube battery forklift. The normal level shall be higher than the bulkhead 15~25mm. Usually check on 10~15 days, hot weather, weekly check. Normally, distilled water should be added when the electrolyte is insufficient. The dilution of the sulfuric acid electrolyte is not permitted unless the level of the liquid is known to be due to an electrolyte dilution. For electrolyte purity should be tested once a year, special circumstances, electrolyte color abnormalities occur, should be tested at any time purity. When the electrolyte is prepared, the sulfuric acid solution shall be in accordance with the GB4554-84, and the pure water shall conform to the industry standard ZBK84004-89 (if the new GB is adopted, the national standard shall prevail). For the electrolyte which needs to be refilled, the solution density is 1.265g/cm3 + 0.005g/cm3 (30 DEG C), and the volume ratio of water to sulfuric acid (density 1.835g/cm3) is about 3.1:1. The mass ratio is about 1.7:1.

For the new battery, the density of the electrolyte at the end of the charge shall be 1.290g/cm3 + 0.005g/cm3 (30 DEG C). When the electrolyte is prepared, the sulfuric acid shall be added to the water in proportion, and the acid proof bar can be stirred at any time so that the mixture can be mixed evenly, and the water is poured into the sulfuric acid to avoid accidents. For by up regulation of Calais electrolyte density, availability of pre prepared 1.40g/cm3 sulfuric acid to adjust. After the electrolyte is injected, it needs to be fixed for a period of time and can be charged until the temperature drops below 35 degrees celsius. The battery used in cold areas has a comparable electrolyte density of 0.020~0.030 g/cm3, while the battery used in hot areas reduces 0.020~0.030 g/cm3. When measuring the electrolyte density, the electrolyte temperature should also be measured at the same time, and the measured electrolyte density will be converted to the density value at 15 degrees. For example, when the electrolyte temperature is 30 degrees centigrade, the density is 1.28 g/cm3, and the density is when it is converted to 15. Moreover, when the electrolyte density is 1.27g/cm3 at -15 degrees centigrade, the density is converted to 15 DEG C: 1.27 g/cm3-0.02=1.25g/cm3. According to practical experience, the density of the electrolyte at 15 degrees C decreases by 0.01 g/cm3 each, which is equivalent to discharge 6%.

Therefore, if the electrolyte density is known, the charge and discharge of the lead-acid battery can be determined. It should be noted that the electrolyte density can not be measured immediately for lead-acid batteries with large current discharges or freshly added distilled water. The electrolyte temperature of forklift battery charging shall not exceed 45 centigrade. When approaching 45 degrees, the charging current or the charging time should be halved, and the charge will be charged until the temperature is below 35. However, the charging time should be extended appropriately. Whether the battery is adequate or not can be judged by the following aspects:

(1) the battery voltage or electrolyte density remained basically stable for 2~3 hours,

(2) a strong bubble exists in the electrolyte level of the battery,

(3) the charging capacity is 4~5 times of the rated capacity, and the charging time is about 70 hours.

Under normal working conditions, forklift batteries should be charged in accordance with the provisions of the timely charging. The normal charge (i.e. additional charge) method; to segment balance current charging method for example: Battery normal charging in the first phase of 0.70I5 (A) as the monomer battery charging current, average voltage up to 2.40V, then 0.35I5 (A) second phase current charging. The charge amount is about 120%~130% of the output power, but the charge of the first 5 times of the new battery should be about 150% of the last discharge. At present, the battery forklift truck charger mostly automatic control type charger, the specific operation method, see the charger instructions. In addition, normal charging must be performed at the time of the following conditions: (1) the electrolyte density drops to 1.150~1.200 g/cm3. (2) winter battery releases 25% of electricity and releases 50% in summer.

扫一扫,手机浏览

扫一扫,手机浏览