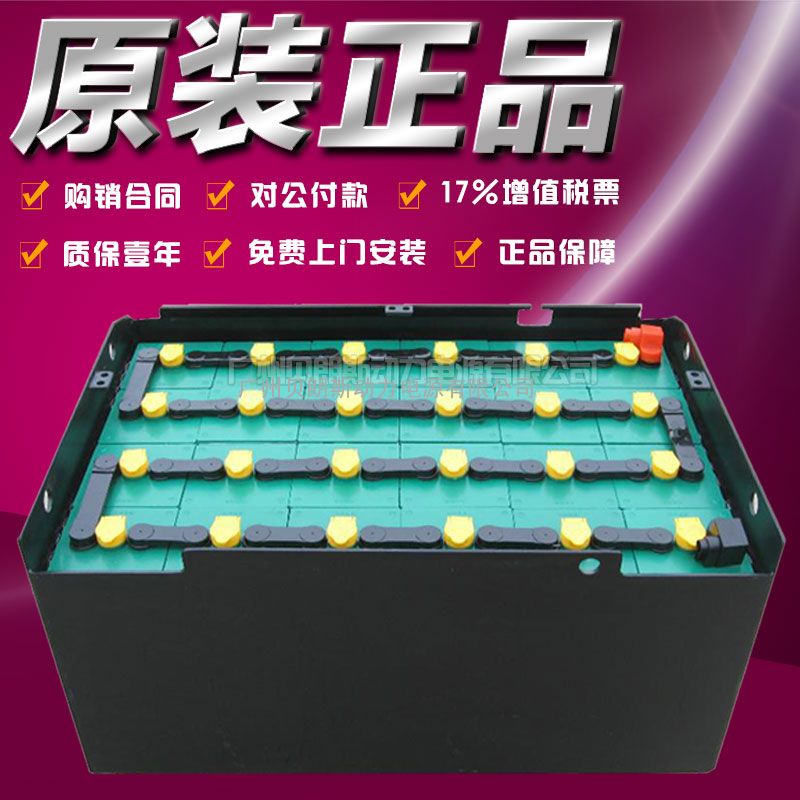

- 宝骊叉车电瓶蓄电池 宝骊铲车铅酸蓄电池24-D-400BS 48V400Ah

详细信息

品牌:贝朗斯 型号:24-D-400BS 48V400Ah 化学类型:铅酸 电压:48V 类型:牵引型 电池盖和排气栓结构:开口式 额定容量:400Ah 外形尺寸:972*636*500 mm 适用范围:叉车 票据支持:13%增值税,销售合同 配送支持:送货上门,全国多地提供安装 宝骊叉车蓄电池型号大全概括了包括全系列电瓶叉车用蓄电池组,可选择DIN、BS系列作为单体串联,不同标准的尺寸不一样,宝骊叉车电瓶品牌可选择淄博火炬、广州贝朗斯、安徽迅启、日本GS、德国HOPPECKE、浙江天能等作为动力来源,不同品牌叉车电瓶价格不一样,使用起来的质量也不同,设计寿命也存在差距,当然作为配套价格也不一样,宝骊蓄电池叉车主要以电瓶为牵引力,广泛在各种港口、工厂、物流公司、饮料公司、仓储公司等场所等到应用, 广州贝朗斯动力电源有限公司是一家*致力于动力电源、储能电源、应急电源、启动电源等领域蓄电池系统方案提供商,设址于美丽的花城—广州,公司的成立,标志着牵引车蓄电池自主品牌正式破题,对于提升国内外电动叉车、风能、电动汽车等产业的自主研发能力具有重要的战略意义,发展的过程中,不断与国内外多个电池科研机构交流合作,吸取世界先进技术,设计开发,规模不断扩大,未来对于叉车、汽车等各版块市场格局变化必将产生深远的影响,是绿色能源先驱智者。 宝骊电动叉车蓄电池一般为管式极 板,以深循环放电作用,需要持续不断工作,对生产铸造工艺要求十分高,特别是板栅,这种属于活性物质,是主要导电的集流体,采用铅锑合金制造,其中配方成 分确定电池后期的续航能力,很多时候进口叉车蓄电池的使用寿命可达5年或者更久,国产的也才2年到3年不等,同款型号,使用情况相差很远,无论是放电、充 电、脱硫等方面,进口叉车电池的性能要比国产强很多。根据不同种 类的电池确定合金铅的规格,然后进行铅炉高温溶化,达到一定的工艺要求后,浇注金属模具,待冷却出模整体存放。控制好电池板栅的质量、厚度、完整性、 尺寸、重量等方面。第三,我们说到了叉车蓄电池的“心脏”,极板是它的核心,极板好坏品质,可以决定电池的寿命,生极板的主要控制参数投膏量、厚度、含酸 值。密度、水分、游离铅含量等几个方面。总之,要想品牌迅速扩大,立足市场,必须有过硬的技术。 叉车电池宝骊叉车电瓶的容量电压根据车辆型号决定,出厂时已经有标准配置容量, 叉车蓄电池顾名思义是用于叉车 上的电池,这种依靠牵引力工作的铅酸电池,是存在自放电的,现在春节就快来临,蓄电池的保管工作依然是个难题,因为很多时候企业放假了,搁置的叉车电池组 会自行走电,当假期结束的时候,很难在充得起电,导致无法开展工作,耽误了叉车的机动性能,如何避免蓄电池因为自放电存在的各中因素,企业应该就工厂事 宜,安排值班师傅,节前,应该充电至饱和状态,把叉车上插接器断开,叉车电池充满电后若处于长期储存状态下,会进入自放电过程,其容量将逐渐减少,且这种 现象是不可避免的。电瓶叉车电池的容量决定它的使 用时间,当到达一定时期的时候,起叉的载重量、行走速度都随着下降,我们如何得知呢?通过什么方法判断?可通过容量检测,用5小时率放电,容量低于 80%,说明活性物质量已不足。解剖后检查极板上活性物质脱落的情况是:蓄电池底部淤积了大量沉淀物,极板表面露出板栅筋条,极板组两侧有大量的铅絮物, 电解液浑浊,呈铁青色。沉淀颜色呈灰褐色,说明铁、铜杂物较多;沉淀物呈浅蓝或灰白色,说明蓄电池中电解液密度高。沉淀是糊状物,说明蓄电池出现温升过 高;沉淀是块状物,则说明制造时有先天不足因素。电瓶叉车电池的容量下降还有一个方法知道,就是在充电的时候,单体达不到一致性,个别电池单体电解液颜色 变黑,底部的沉淀物质会浮起来,导致盖子的颜色边黑色,打开盖子可以见到很多粉末状的物体。

广州贝朗斯公司长期配套宝骊叉车蓄电池,质量稳定,性价比高,配送及时,全国各地都有分销商,快速提供响应服务。电动叉车蓄电池是一种牵引作 用力的电瓶组,用多个单体串联不同的电压使用,工作强度比其他使用领域要高很多,很多用户注意到,使用一段时间后,这种电池的单体出现不平衡的状态,有些 容量高,有些很低,一旦干水后,全部单体叉车电瓶比重密度偏差很远,对于这种现象我们做了以下分析:单个蓄电池的电压与容量有限,在很多场合下要组成串连 蓄电池组来使用。但蓄电池组的中的电池存在均衡性的问题。如何提高蓄电池组的使用寿命,提高系统的稳定性和减少成本,是摆在我们面前的重要问题。蓄电池的 使用寿命是由多方面的因素所决定,其中***重要的是蓄电池本身的物理性能。此外,电池管理技术的低下和不合理的充放电制度也是造成电池寿命缩短的重要原因。 对蓄电池组来说,除去上述原因,单体电池间的不一致性也是个重要因素。针对蓄电池充放电过程中存在的单体电池不均衡的现象,笔者分析比较了目前的几种均充 方法,结合实际捉出了无损均充方法,并进行了试验验证。现有的均衡充电方法:实现对串联蓄电池组的各单体电池进行均充,目前主要有以下几种方法。

在电池组的各单体电池上附加一个并联均衡电路,以达到分流的作用。在这种模式下,当某个电池首先达到满充时,均衡装置能阻止其过充并将多余的能量转化成热能,继续对未充满的电池充电。该方法简单,但会带来能量的损耗,不适合快充系统。在充电前对每个单体逐一通过同一负载放电至同一水平,然后再进行恒流充电,以此保证各个单体之间较为准确的均衡状态。但对蓄电池组,由于个体间的物理差异,各单体深度放电后难以达到完全一致的理想效果。即使放电后达到同一效果,在充电过程中也会出现新的不均衡现象。定时、定序、单独对蓄电池组中的单体蓄电池进行检测及均匀充电。在对蓄电池组进行充电时,能保证蓄电池组中的每一个蓄电池不会发生过充电或过放电的情况,因而就保证了蓄电池组中的每个蓄电池均处于正常的工作状态。Baoli forklift battery 3.07ghz summarized including the full range of electric forklift batteries, can choose DIN, BS series as a single series of different standards, the size is not the same, Baoli forklift battery brand choice Zibo, Guangzhou Bay, Anhui torch Langsi Xunqi, Japan GS, Germany HOPPECKE, Zhejiang as the day the source of power, different brands of forklift battery price is not the same, the quality of use is different, the design life there is a gap, of course, the price is not the same as supporting, Baoli forklift battery with battery for traction, widely used in various ports, until factories, logistics companies, beverage companies, warehousing companies and other places. Guangzhou Bei rance power supply Co. Ltd. is a professional committed to the power supply, energy storage power supply, emergency power supply, power supply etc. start battery system Solutions provider, located in the beautiful city of Guangzhou, the establishment of the company, marking the tractor battery brand official title,

has an important strategic significance for the promotion of domestic and foreign wind power, electric forklifts, electric vehicles and other industries the ability of independent research and development, process development, and a number of domestic and foreign battery research institutions the design and development of exchanges and cooperation, learn from the advanced technology in the world, and continues to expand the scale of future changes in market structure, each part of forklift cars will have a far-reaching impact, is the pioneer of green energy wise. Baoli electric forklift battery is generally tubular plate, with the deep circulation discharge effect requires continuous work, the demand is very high casting production process, especially the grid, this belongs to the active substance, is the main conductive collector, the lead antimony alloy manufacture, the formula composition of late battery endurance when a lot of imported forklift battery life up to 5 years or more, China has only 2 years to 3 years, with models, far from use, whether it is charging, discharge, desulfurization, performance of imported forklift battery is much better than domestic strong. According to the different types of batteries to determine the specifications of alloy lead, and then lead furnace melting at high temperature, to meet the requirements of the process, pouring metal mold, to be cooled, the mold stored as a whole. Control the quality, thickness, integrity, size and weight of the grid. Third, we talked about the "heart" of the forklift battery, the polar plate is its core, the quality of the plate is good, it can determine the battery life, the main control parameters of the polar plate, paste quantity, thickness and acid value. Density, moisture content, free lead content and so on. In short, in order to quickly expand the brand, based on the market, we must have excellent technology.Baoli forklift battery capacity voltage according to the type of vehicles, the factory has a standard capacity, as the name suggests is used for forklift forklift battery batteries, lead-acid batteries with traction work this is the existence of self discharge, now the Spring Festival is coming soon, battery storage work is still a problem, because most of the time business holiday, will use a forklift battery group, at the end of the holiday, it is difficult to afford in the charge of electricity, to carry out the work, delayed the maneuvering performance of the forklift, how to avoid the battery for the self discharge factors exist, enterprises should be the factory matters assigned to duty master, before the holiday, should be charging to saturation, the forklift connector is disconnected, forklift battery is full of electricity in long-term storage conditions, will enter the self discharge. Its capacity will gradually decrease, and this phenomenon is inevitable. The battery capacity of the battery forklift truck determines its service time. When it reaches a certain period of time, how much do we know about the weight and the walking speed of the fork? By what method? Capacity test, with 5 hours discharge, capacity less than 80%, indicating that the quality of active substances is insufficient. After the inspection on the plate anatomy of active material shedding situation is: a large number of sediment deposition at the bottom of the battery, the plate surface exposed grid stiffened plate group, both sides have a lot of electrolyte of lead floc, turbidity, iron is blue. The color is gray brown precipitate, indicating more iron and copper impurities; sediment was light blue or gray white, indicates that the battery electrolyte in high density. Precipitation is a paste, indicating that the battery temperature rise is too high; precipitation is a block of things, it shows that the manufacture of congenital deficiency factors.

Battery forklift battery capacity decline and know a method that is in charge when the monomer is not up to the consistency of individual cell electrolyte color black, the sediment at the bottom of the float, leading edge lid color black, open the lid and you can see a lot of powder shaped object.

Guangzhou Bei Langsi Baoli forklift battery supporting company's long-term, stable quality, competitive price, timely delivery and have distributors all over the country, providing rapid response service. Electric forklift battery is a battery group traction force, with a single series of different voltage, the intensity of work is much higher than other areas of use, many users noted that after a period of time, monomer unbalanced in the cell, some high capacity, some very low, once dry water, all of the monomer battery forklift proportion density deviation very far, for this phenomenon, we made the following analysis: single battery voltage and capacity is limited, on many occasions to form a series of battery to use. But the battery in the storage battery has the problem of proportionality. How to improve the service life of the storage battery and improve the stability and decrease of the system?

-

-

内容声明:谷瀑为第三方平台及互联网信息服务提供者,谷瀑(含网站、客户端等)所展示的商品/服务的标题、价格、详情等信息内容系由店铺经营者发布,其真实性、准确性和合法性均由店铺经营者负责。谷瀑提醒您购买商品/服务前注意谨慎核实,如您对商品/服务的标题、价格、详情等任何信息有任何疑问的,请在购买前通过谷瀑与店铺经营者沟通确认;谷瀑上存在海量店铺,如您发现店铺内有任何违法/侵权信息,请在谷瀑首页底栏投诉通道进行投诉。广州贝朗斯动力电源有限公司 电话:020-86603123 手机:15918430146 地址: 广州市白云区夏花二路28号

扫一扫,手机浏览

扫一扫,手机浏览