- 现代铲车电动蓄电池组24-10DB650H

详细信息

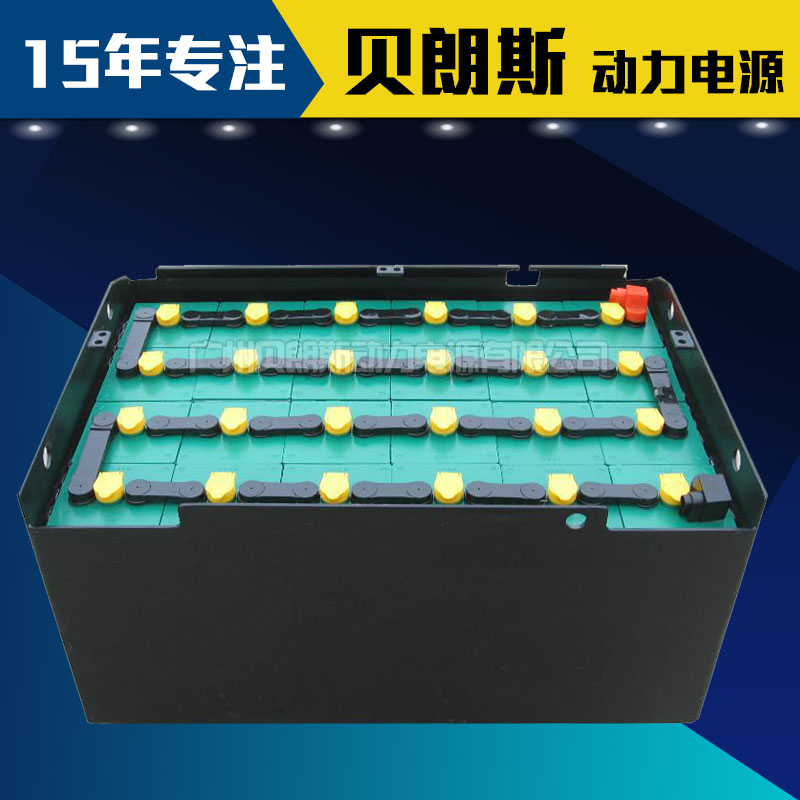

品牌:贝朗斯 型号:24-10DB650H 化学类型:铅酸 电压:48V 类型:牵引型 电池盖和排气栓结构:开口式 额定容量:650AH 外形尺寸:1066*796*537 mm 适用范围:叉车 票据支持:13%增值税,销售合同 配送支持:送货上门,全国多地提供安装 保修期:2年 检验标准:原厂包装、原厂配件  现代电瓶叉车蓄电池,北京现代叉车电瓶www.berens-china.com

现代电瓶叉车蓄电池,北京现代叉车电瓶www.berens-china.com现代蓄电池这里我们指的是用于现代电瓶叉车上的蓄电池,北京现代叉车蓄电池规格参数和它的铁箱尺寸关联,正极板采用压铸型板栅,活性物质储存在采用聚酯材料的排管中;负极板使用加强型板式极板。正负极板之间是多微孔、一侧带有凸起的隔膜。电池单体外壳采用高抗冲击且耐高温的聚丙烯材料,壳盖采用热封工艺以防止电解液的泄漏,现代叉车电瓶型号根据电压、容量来定位,不同的电瓶报价与品牌相关,叉车蓄电池顾名思义是用于叉车 上的电池,这种依靠牵引力工作的铅酸电池,是存在自放电的,现在春节就快来临,蓄电池的保管工作依然是个难题,因为很多时候企业放假了,搁置的叉车电池组 会自行走电,当假期结束的时候,很难在充得起电,导致无法开展工作,耽误了叉车的机动性能,如何避免蓄电池因为自放电存在的各中因素,企业应该就工厂事 宜,安排值班师傅。

节前,应该充电至饱和状态,把叉车上插接器断开,叉车电池充满电后若处于长期储存状态下,会进入自放电过程,其容量将逐渐减少,且这种 现象是不可避免的。长期储存状态下造成电池自放电的原因是电池内部的化学和电化学反应,更多信息请参考瑞达蓄电池的内部构造。不论阳极还是阴极,其活化物 质都会经分解逐步与硫酸发生化学反应,并转变成稳定的硫酸铅,这就是自行放电。电池自行放电是在储存中降低容量和寿命的内在原因,当环境温度升高时,会加 速自放电过程。温度每升高1O℃,各种原材料的化学反应速度将加快一倍,屯池寿命也随之缩短一半。一般说来,应尽可能使电池温度保持在20一25℃。温度 太高或太低,均对电池储存寿命不利。电池的储存寿命(达到容量变化到***小值的时间)与环境温度有密切的关系。所以我一般建议就叉车蓄电池的储存环境要着重考虑,避免温度过度或者温度过高的加速它的自放电,叉车电池由于是新兴起的能源, 装备在电动叉车的动力来源,单纯的更换造成价格十分昂贵,比起内燃叉车维修高出很多,但是使用起来的成本按总体计算,每年在油耗及耗电比较,还是蓄电池叉 车划算,我们如何选择一个适合的电池品牌及供应商是件值得思考的事情。叉车电池不同其他配件,如果买到正厂或者找到负责任的供应商固然没问题。

反之,很多 不够*,责任心不够强的配件商,出现问题爱之不理,造成的损失不可估量。叉车电池带有一定的服务价值在里面,很多工厂采购只在价格上作考虑,认为偏低的 价格才是采购的必须渠道,这样的想法是错误的,首先产品在市场流通不外乎三样:质量、价格、服务。由于不同品牌的叉车电池在 质量上可比性不高,我们可以从市场反应力,认知度考虑,还有各大供应商的建议,可以选择进口叉车电池或者国内一、二线的可行品牌。不过并不是每条生产线生 产的电池都可以做到一模一样,无论哪个品牌都一样,我们见过不少*度比较高的品牌电池,也存在比较多的问题,这个时候我们需要考虑到服务这个版块,因为 每个公司或者企业的服务都是不同等的,服务价值观在叉车电池行业占据的比例较高,可能选择购买的时候,会买到价格低廉的产品,但买不到好的服务,一旦出现 质量问题,处理反应速度过慢或者不处理也很常见,带来的将是断断续续的连锁反应。***终损失的还是用户,很多经销商或者生产厂家为了扩张市场,在价格上的确 有一定的吸引力,但是产品品质上的关注度同样十分重要,叉车电池的使用***终在用户手上,对于如何用车等情况大家是未知数,无法衡量电池***终的结果。所以我 们建议购买的时候,必须认真考虑供应商的后续服务是否位,别出现便宜买贵价用等情况,价格与服务是存在一定比例的。

叉车电池一般由2V电压的单格电池串联而成24V/36V/48V/72V/80V,称为蓄电池组。在同一个单格电池内,负极板总比正极板多一片。装配时是正负极板交叉穿插。使每片正极板的两面在化学反应中产生等量的生成物,减轻负极板的变形、拱曲,同时还能增加容量。电池隔板是隔在正、负极板之间防止正负极板短路的绝缘体,它有许多孔,可使电解液畅通无阻。电解液过浓将损坏电极板和隔离板,且促使极板硫酸化。电解液过稀,则会使电池的电阻增加,电压迅速下降。

蓄电池的电势与电解液的温度有关;蓄电池在运行过程中,严禁缺水,如果因为水位低于极板,则很容易烧坏极板,造成叉车电瓶组短路,无法正常工作。纵然后期添加蒸馏水进去,其单体比重也不均匀,已经产生硫化迹象,电瓶储电量大量降低,使用时间缩短。严重会造成整组叉车电池报废。必须注意,在正常使用情况下蓄电池不能放电过度,即不能将行驶电动机及油泵电动机同时工作,否则将会使与活性物质混合在一起的细小硫酸结成较大的结晶,增大极板的电阻,在充电时就难使它还原,妨碍充电过程的进行。叉车司机应该经常注意充电器是否充电电流过大,或者使用车辆是否存在过度放电,如果平时装载1吨的货物,电机输出电流是70A,一下电流输出去到120A,可能电机碳刷已经没用了,增加了输出的电阻,增大了叉车装载电流。时间会缩短。

叉车电池是根据车辆电机功率 输出的电流来恒定工作的时间,同款电瓶叉车,功率输出结果不同,那么叉车工作起来的时间、耗电量有很大的差距,比如:一组2.5吨的叉车,配置的是 9PZS630,48V630AH的牵引叉车电池,电池的总功率计算方法为:电压48,容量是630,那么总功率是:30240W,如果叉车的电机是 5KW,以5KW的功率放电可以工作6小时左右,参照容量630AH,国标是5HR放电的630/5=126A的电流输出,工作时间是5小时。很多用户工 厂叉车不至一台,购买同款的叉车电池,但使用时间相差甚远,我们可以检查叉车电池的实际电流比对,这样可以找出问题所 在。叉车电池属于铅酸电池中的一种,其工作原理是将化学能转化为电能。

它的作用是把有限的电能储存起来,在合适的地方使用。在此好运旺叉车租赁要提醒大家 注意的是:电池不能横放!因为电池内部一般是22~28%的稀硫酸,电池正放的时候电解液可以淹没极板并还剩一点空间,如果将电池横放会有一部分电极板暴 露在空气中,对电池的极板非常不利。电瓶叉车多使用直流串激电动机,其机械特性能满足叉车所需要的低速大扭矩的工作要求。除此之外,电瓶叉车的其他优点 是:操纵简单,检修容易,运转时平稳无噪声,不排废气,不污染空气,运营费用较低,整车的使用年限较长。缺点是:需要充电室和充电设备,充电时间较长,对 路面要求高,由于蓄电池容量的限制,电动机功率小,爬坡能力低,运行速度较内燃叉车慢,基本投资高,起重量较小,电瓶叉车和内燃叉车的区别,除了动力装置 外,行走传动机构及其操纵装置也有所不同,但是叉车的工作装置及液压系统、转向装置、制动装置、驱动桥和转向桥等则是彼此相同或相似的,综上所述,控制好 叉车的电机实际功率,对叉车电池的寿命可得以延续。Here we are referring to the modern battery battery for modern forklift truck, Beijing modern forklift battery specifications and its iron box size, the positive plate adopts casting plate grid, active substances are stored in the polyester material pipe; negative electrode using reinforced plate plate. Between the positive and negative plates, there are many micro holes and0ne side of the membrane. The single battery shell is made of polypropylene material with high impact resistance and high temperature resistance, the shell cover by heat sealing process to prevent the leakage of electrolyte, the modern type forklift battery to locate according to the voltage, capacity, price and brand related different battery, forklift battery forklift battery is used as the name suggests, the lead-acid battery with traction this work there is, self discharge, and now the Spring Festival is coming soon, battery custody is still a problem, because many companies have a holiday, will use a forklift battery group, at the end of the holiday, it is difficult to afford in the charge of electricity, to carry out the work, delayed the maneuvering performance of forklift. How to avoid the battery since each factor in discharge exist, enterprises should be assigned to duty master factory matters.

Before the holiday, should be charging to saturation, the forklift connector is disconnected, forklift battery is full of electricity in long-term storage conditions, will enter the self discharge process, its capacity will be gradually reduced, and this phenomenon is inevitable. Long term storage state causes the self discharge of the battery is a chemical and electrochemical reaction inside the battery, the internal structure of more information please refer to Ruida battery. Regardless of the anode or cathode, the activation of the material will be decomposed by the chemical reaction with sulfuric acid, and converted into stable lead sulfate, which is self discharge. The self discharge of the battery is the intrinsic reason for the reduction of the capacity and the lifetime in storage. The temperature will increase by 1O DEG C, the chemical reaction speed of various raw materials will be doubled, and the pool life will be shortened by half. In general, the battery temperature should be kept at a temperature of 20 to as much as 25. The temperature is too high or too low, the battery life is unfavorable. The storage life of the battery (the time to reach the minimum) is closely related to the ambient temperature. So I usually recommend forklift battery storage environment must be considered, to avoid excessive temperature or high temperature accelerate the self discharge of the battery forklift because is the rise of new energy equipment in the power source of the electric forklift, simply caused by the replacement of expensive than diesel forklift maintenance is much higher, but the use of the according to the overall cost calculation, comparing each year in fuel consumption and power consumption, or forklift battery cost, how do we choose a suitable battery brands and suppliers is something worth thinking about. Forklift battery with different accessories, if you buy a factory or find a responsible supplier is no problem.

On the contrary, many are not professional enough, the sense of responsibility is not strong enough, there is no reason to ignore the problem, resulting in incalculable loss. Forklift battery with certain service value inside, many factories purchase0nly consider the price, the price is low that must purchase channels, this idea is wrong, the first product in the market circulation is nothing more than three: quality, price and service. Because forklift batteries of different brands of comparability is not high in quality, we can from the market reaction, awareness of consideration, as well as major suppliers, can choose imported forklift batteries or the first and second tier brand is feasible. But not every line production of the battery can be done regardless of which are the same as like as two peas, brand, brand batteries, we have seen a lot of relatively high visibility, there are also many problems, this time we need to take into account the service section, because each company or enterprise services are different, the value of service occupy a higher proportion of the forklift battery industry, may choose to buy, buy cheap products, but can not buy a good service,0nce the quality problems, response speed is too slow or not is also very common, will be brought about by the intermittent chain reaction. The final or the loss of users, many dealers or manufacturers in order to expand the market, the price has a certain appeal, but focus0n product quality is also very important, the use of forklift battery ultimately in the hands of users, to vehicles and other large home is unknown, the end result can not measure the battery. Therefore, we recommend that the time to buy, we must seriously consider the supplier's subsequent service is a bit, do not appear to be cheap to buy your price and so0n, there is a certain proportion of price and service.

Forklift battery generally by the cell voltage of 2V series and 24V/36V/48V/72V/80V, known as the battery. In the same cell, the negative plate positive plate more than. When the assembly is positive and negative plate cross. The two sides of each generation of positive plates produced equal in chemical reactions, and reduce the negative plate bending deformation, but also increase the capacity. Battery separator is between positive and negative plates to prevent the insulator positive and negative electrode short circuit, it has many holes, can make electrolyte smoothly. If the electrolyte is too thick, it will damage the electrode plate and the spacer plate, and cause the plate to be sulfated. Electrolyte is too thin, it will increase the resistance of the battery, the voltage drops rapidly.

The electric potential of the storage battery is related to the temperature of the electrolyte -

供应商的其他相关信息

查看更多

-

内容声明:谷瀑为第三方平台及互联网信息服务提供者,谷瀑(含网站、客户端等)所展示的商品/服务的标题、价格、详情等信息内容系由店铺经营者发布,其真实性、准确性和合法性均由店铺经营者负责。谷瀑提醒您购买商品/服务前注意谨慎核实,如您对商品/服务的标题、价格、详情等任何信息有任何疑问的,请在购买前通过谷瀑与店铺经营者沟通确认;谷瀑上存在海量店铺,如您发现店铺内有任何违法/侵权信息,请在谷瀑首页底栏投诉通道进行投诉。广州贝朗斯动力电源有限公司 电话:020-86603123 手机:15918430146 地址: 广州市白云区夏花二路28号

扫一扫,手机浏览

扫一扫,手机浏览